ATLAS Thin Gap Chamber

Cable connection between ASD and PS-Pack

B.J. Ye(a) , T.Takeshita(b), K.Hasuko(a), T. K.Ohska(c)

O.Sasaki(d), T.Kobayashi(a)

(a)ICEPP, University of Tokyo, Japan

(b)Physics Department, Shinshu University, Japan

(c)International Collaboration Office, KEK, Japan

(d)Institute of Particle and Nuclear Studies, KEK,Japan

Contact person:

Bangjiao Ye, bjye@online.kek.jp and Tohru Takeshita, tohru@shinshu-u.ac.jp

This document is avarable in a pdf file (400kb) , as well.

1. Introduction

This is a draft design of the connection between Amplifier-Shaper-Discriminator

(ASD) Boards, Patch-Panel (PP) and Slave Boards (SLB) for the

front-end electronics of the Thin Gap Chamber (TGC) trigger system.

We will discuss cable route, mount, its length and weight as well

as time delay.

The ATLAS experiment in the LHC uses TGC as its forward muon trigger

detector. The TGCs are mounted in six big wheels, M1, M2 and M3

in each side(A and C) which support mechanically. M1 has three

TGC layers, called as triplet. M2 and M3 both have two TGC layers

called as doublet. The inner wheel is a doublet of TGC. The total

number of TGCs is about 3600. The total number of TGC signals

for wires and strips is nearly 321k channels.

A PS-Pack serves 1/24th of triplet (M1) or two doublets (M2 and

M3). A sub-PS-Pack consists of 1 mother Patch-Panel (PP) board,

2 daughter PP boards and 2 Slave Boards (SLB), which is called

a standard sub-PS-Pack unit. A sub-PS-Pack unit is shown in Fig.1

schematicaly. The signals from the Amplifier-Shaper-Discriminator

(ASD) Board are sent though a 20-pair twisted-pair cable to the

PS-Pack. Each ASD Board consists of 4 ASD chips which corresponds

to 16 wires/strips channels. Each unit of sub PS-Pack serves 16

ASD Boards which equals to 256 channels in the maximum (one exception

exists in doublet which serves 18 ASD Boards corresponding to

258 channels) for doublet.

The wheels M1, M2 and M3 are divided into 24 identical elements, called sets. Three sets make an octant. Each set is divided radially into two regions, named Forward and End-cap.

The ASD Board is physically attached to the edge of a TGC and

enclosed inside the TGC electrical shielding (Faraday cadge).

Signals from the ASD Boards are sent to a Patch-Panel (PP) board,

which houses receivers for the ASD outputs, TTC receivers and

DCS, Bunch-Crossing Identification circuits, logic to take care

of physical overlap in the TGCs and fan-outs. Outputs from the

PP board are sent to corresponding Slave Board (SLB) where the

coincidence and read-out circuits are placed. For M1 wheel, three

groups of two ASD Boards are served by a SLB, which allows a 2-out-of-3

coincidence to be formed. For M2/M3 wheels, four groups of two

ASD Boards are served by each SLB and a 3-out-of-4 coincidence

is made.

The PS-Pack, which consists of PP and SLB, are placed on the accessible

surfaces of the TGC wheels. Thus, PS-Pack for the M2 and M3 are

mounted on the outer surface of the M3 wheel and those for the

M1 are mounted on the inner surface of the M1 wheel.

The powers of PS-Packs are about 185W/set for doublet and 80W/set

for triplet. Total power of PS-Pack is 13kW which will most transfer

into heat. A cooling system is needed for removing heat. The double

U-shape coolant pipe system has designed for cooling the PS-Pack.

The cooling pipes made of Al is used not only as cooping pipes

and but also as support bars for the PS-Pack. Low voltage is supplied

by LV bus which consists of 4 wires (3.3V, ±3V and common ground)

as shown in Fig.2.

The total number of electronic channels in the TGC system is 321k.

The details of the channel distribution over the four sub-wheels

are given in Table 1. Table 2 gives the total number of channels,

ASD Boards and SLBs for a set (1/24), octant, one side and both

sides.

There are 35 SLBs per set for the doublet, 23 SLBs for the triplet

and 2 SLBs for the inner wheel. In order to reduce physical size

of a PS-Pack, a high-density connector (KEL, 8830E-080-170L) is

used at the PP board. With this connector, the length of a sub-PS-Pack

can be designed to be 510 mm. Because the avairable radial length

on the outer surface of M3 wheel is only 6000 mm, we arrange the

PS-Pack in two layers construction. It occupies 5000 mm in length

including Service PP board. We arrange all sub-PS-Packs in one-line

configuration so that other service systems such as LV supply

and cooling system can be simply in construction.

For the PS-Pack of triplet, it is a bit more complex than that

of doublets because the support bar of TGC limits the avairable

length on the inner surface of M1 wheel. The total usable radial

length is 2500 mm, however, we need 3200 mm to arrange all sub-PS-Packs

for M1 in one-line. We still designed all sub-PS-Pack units in

one line which is based on the assumption that the support bar

can be moved to the center of two TGCs by about 100 mm which can

increase the available length to 3200 mm.

Table 1 The number of Channels, ASD chip, ASD Board, PP and SLB

* For Inner wheel, each TGC has a slave board, that is, it combines wires and strips in one SLB.

Table 2 The number of channels, ASD Board and SLB

2 Connection between ASD and PS-Pack

2.1 ASD connector name

As have given above, each PS-Pack set which is a 1/24 of a wheel,

contains 141 ASD boards for triplet and 276 ASD boards for doublet.

For triplet, middle layer (TGC1) has 35 connectors and two sides

(TGC0 and TGC2) both have 53 connectors because there is not strip

output in the middle layer. For doublet, there are 70 connectors

per layer for M2 and 68 connectors per layer for M3. In order

to make a distinction for different ASD boards, we name each connector

of ASD boards as shown in Table 3.

TGCs were installed on both sides of ATLAS with a mirror structure

as shown in Fig.3. We use ÒAÓ to present the TGCs which located

in positive Z region and ÒCÓ present the TGCs located in negative

Z region. We use M1, M2 and M3 to present the three wheels. M1

is a triplet consisting of A, B and C layers. M2 and M3 are doublet

consisting of A and B layers. Each name of ASD connector for 1/24

wheel is shown in Fig.4 and Fig.5 for triplet and doublet, respectively.

Fig.3 TGC location and wheels

Table 3 ASD connector naming

Figure 4, ASD positions for Triplet.

Figure 5, ASD positions for Doublet.

2.2 Sub-PS-Pack names and arrangement

Patch Panels and Slave Boards are assembled into PS-Pack. There

are two kinds of PS-Pack: one is for the triplet (mounted on the

surface of M1 wheel) and another is for the doublet( M2 and M3,

mounted on the surface of M3 wheel). All sub-PS-Packs for 1/24

unit were arranged as two layers (upper and bottom layers). In

order to predigest the support scheme and cooling system, all

sub-PS-Packs are arranged in one-line structure. Total length

of a PS-Pack is 3.2m for triplet and is 5.0m for doublet, respectively.

Total numbers of PS-Packs are 24,24 and 8 for triplet, doublet

and inner wheel. Their names are given in Table 4.

Table 4 PS-Pack naming

Table 5 Patch Panel naming

Table 6 Slave Boards naming

Triplet example

Fig.6 Sub-PS-Pack location name for PP and SLB for Triplet

Doublet example

Fig. 7 Sub-PS-Pack location name for PP and SLB for Doublet

2.3 PP Connectors names

As mentioned before, each PP has two layers: one mother PP

and two daughter PPs. Each mother PP has 4 high density connectors

( one exception exists in doublet mother PP with 5 connectors)

and each daughter has 2 high density connectors. In order to distinguish

each connector in the same PP board, we give names to the connectors

as shown in Fig.8.

Fig.8 PP connectorÕs names

The connector named to be E0WD0-MA, for example, is the first connector (R is larger than others connectors in same PP) on the mother PP for the Patch Panel E0WD0 and also E0WD0-DC is the third connector on the daughter PP for the same PP. Since each PP connector connects to 2 ASD-board connectors, we have to distinguish the different part of in one connector. Upper part (R is larger, the green part in Fig.8) can be signed as 1 and bottom part as 2. Therefore, connector DA1 means the upper part of connector DA.

2.4 Connection between ASD boards and PP

The 16-ch ASD Board has designed and built for both wire signals

and strip signals from TGCs. Each board contains 4 ASD ICs with

protection circuits. The ASD borad is directory attached to the

TGC chamber. The ASD Board design is common for all TGC chambers.

16 LVDS logic signal outputs from the ASD Board are transmitted

through a 20-pair twisted-pair cable from an ASD board. An amplified

analog output through a LEMO type connector is equiped for each

ASD. DC power, ground, threshold voltage and test pulse are supplied

to the ASD Board by the same twisted-pair cable.

Each PP board consists of one mother PP and two daughters PPs

(in some case one PP board consists of one mother PP and one daughter

PP in order to save space). High density connectors are used as

the connectors which receive signal from ASD Board in both mother

and daughter PP. Each PP connector responds to two ASD boards

by the twisted-pair cable. The connection between ASD Board and

PP Board has two kinds of scheme: one is common connection and

another is special connection scheme which is a exception of common

connection. Fig.9 and Fig.11 are the common connection scheme

for doublet and triplet, respectively. Fig.10 and Fig. 12 are

two special connection for doublet and triplet, respectively.

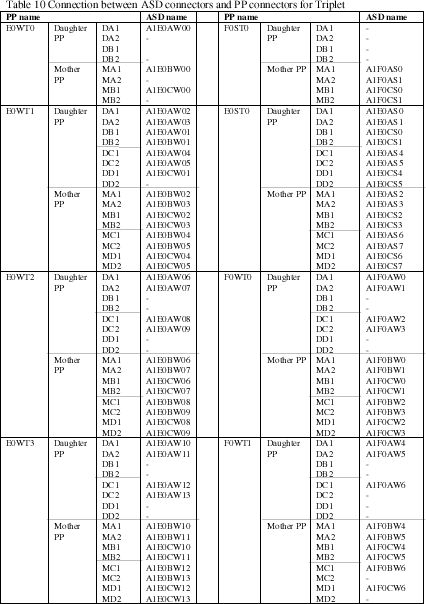

All ASD connector connected to PP connector is one by one as shown

in Tables 8-11 for doublet and triplet.

Fig.9 Normal connection between TGC connectors and PP connectors

for doublet

Fig.10 An exception for the doublet PP board with three connectors

Fig.11 Normal connection between the ASD connectors and PP connectors for the triplet

Fig.12 An exception for triplet PP board

Table 8 Connection between ASD connectors and PP connectors for Doublet Endcap wires

* There is no A3E0A(B)W06 connectors

Table 9 Connection between ASD and PP on doublet for Forward Strip/Wire and Endcap Strip

Table 10 Connection between ASD connectors and PP connectors for Triplet

2.4 Mount scheme and cable route

The TGC system consists of two sides, A and C, which are mirror images of each other. The ASD Boards in TGCÕs edges are also different location as shown in Fig.13. We have considered this difference in the design of PS-Pack in order to decrease the cable length. Two kinds of PS-Pack were designed to meet the requirement for A and C sides: normal PS-Pack and upside-down PS-Pack as shown in Fig.14. In this case, about 1 ton flat cable can be reduced.

Fig.13 The location of ASD boards in TGC edge for A and C sides,

looking at the TGC from the interaction.

Fig. 14 Two kinds of PS-Pack schemes for both A and C sides, looking at the TGC from the interaction.

PS-pack located in the surface of M1 and M3. Total length is

5m and 3.2m for doublet and triplet as shown in Fig.15. The cooling

pipe which has two parallel holes inside for coolant as shown

in Fig.16 is also used as support bar of the PS-Pack. Additional

4 bars for support PS-Pack on the surface of TGC are needed for

doublet and 3 bars for triplet. These additional bars are fixed

with TGC support frames.

Fig.15 The location of PS-Pack in the 1/24 set

Fig.16 Cross section of the cooling pipe made of Al.

Each PP connector receives wire and strip signals which come

from different ASD Board by flat cables. The connection relation

between PP connector and ASD board is shown in tables 8-10. The

length of each flat cable has been estimated according to both

locations of PP connector and ASD Board as shown in Appendix.

Fig.17 shows the cable route for 1/24 of M3 wheel and Fig18 shows

a cable connection between M2 and M3 wheels. The cables from M2

wheel are grouped in a few groups. Some cable support bars are

needed for fixing the cable as shown in Fig.18 between M2 and

M3

Each PP connector receives wire and strip signals which come from

different ASD Board by flat cables. The connection relation between

PP connector and ASD board is shown in tables 8-10. The length

of each flat cable has been estimated according to both locations

of PP connector and ASD Board as shown in Appendix. Fig.17 shows

the cable route for 1/24 of M3 wheel and Fig18 shows a cable connection

between M2 and M3 wheels. The cables from M2 wheel are grouped

in a few groups. Some cable support bars are needed for fixing

the cable as shown in Fig.18 between M2 and M3.

Fig.18 Cable route between M2 and M3

3. Cable length, weight and time delay

3.1 Cable length and weight

Cable weight is a very important factor for the design of the

big wheel. We suppose that it uses flat cable without shielding.

The weight of flat cable with 40-wires is 0.2kg per meter. According

to the positions of the ASD connector and the PP connector, we

can estimate each length of the cable and also the total length

though. Table11 shows the length of cables for one PS-Pack set,

one side and total. If we consider that about 10% additional cable

is required for installing in turning the corner. The total length

of flat cable is about 70 km and 14 tons. The length of the cable

for each ASD connector link to PP connector is given in Appendix.

Table 11 Length and weight of cable

3.2 Time delay

In ATLAS, TGC is chosen for the trigger chamber in the end-cap.

It covers the pseudo-rapidity rang 1<h<2.4. TGC has excellent

timing resolution providing safe bunch-cross identification, owing

to their narrow gap. The trigger system is based on a coincidence

between a hit in the last station(M3) and a corresponding hits

in the second (M2) or/and first station (M1). The low-pT trigger

formed by a 3 out of 4 coincidence in TGC2 and TGC3. For the high-pT

trigger an additional 2 out of 3 coincidence in the triplet of

TGC1 is required.

The arrival timing of a signal at the input of the PP consists

of three parts: time of flight (TOF) of particles from colliding

point to TGC, signal transfer time from hit point inside of TGC

to the edge of TGC along the wire or strip and the signal transfers

time in the cable from ASD board to PP. Time delay depends on

the position of the hit point, size of TGC and length of cable.

Two type of TGCs, doublet and triplet, are located at about 14

m from the interaction point in the beam direction (z). Nine kinds

of different TGCs are taken into account for the time calculation.

The length of cable from ASD to PP depends on the locations of

ASD Board and PP. The arrived time of signal in PP is then expressed

as:

T=TOF+L1/v1+L2/v2

where TOF=L0/v0 , L0 is the flight distance from the interaction

point to the TGC as shown in Fig.19 and v0 is particle velocity

which is nearly equal to the light velocity , L1 is wire/strip

length from the hit point inside of TGC to ASD Board, v1 is the

propagation velocity of wire signal (27cm/ns) or of strip signal

(15 cm/ns), L2 is the cable length from ASD Board to PP, v2 is

the signal transfer velocity along the cable. In the calculation,

a half length of wire/strip for each TGC was assumed. The results

are shown in Fig.20 for doublet and Fig.21 for triplet. The arrived

time of signal to PP are from 66 ns to 80 ns for doublet and from

65 ns to 82 ns for triplet. The relative delay are shown in Fig.22

for doublet and Fig.23 for triplet.

The timing setup in a PP is very important because the asynchronous

TGC signals are bunched by bunch-crossing identification (BCID).

The time delay will be adjusted by an adjustable delay with 25

ns in a step 780ps in PP. The cable delay time is also tested

by test pulses which generated in PPs, that is, the ASD Boards

accepting the test pulses soon return them back to the PPs.

Fig.19 Timing calculation scheme in the end-cap

Fig.20 Time delays for each connector for the doublet

Fig.21 Time delays for each connector for the triplet

Fig.22 Relative time delays for the doublet

Fig.23 Relative time delays for the triplet

Appendix Minimum length of cable and time delay for double